EFFECT OF STERILIZATION ON MECHANICAL PROPERTIES OF COLLAGEN-BASED COMPOSITE TUBES

In this study, composite tubes wer manufactured from biological collagenous matrix and reinforcing polyester mesh. The effect of sterilization on mechanical properties of this structure was evaluated using inflation-extension tests. Samples were exposed to two types of sterilization (ethylene oxide and gamma irradiation). The control (non-sterilized) samples were also tested. The closed thick walled tube model was used in order to compute stresses within sterilized and control specimens. It was found that the process of sterilization (especially irradiation) dramatically affects the final mechanical properties of the material. These findings should be taken into account when such collagenous material is assumed to be used in tissue engineering.

Keywords:

biological composite, sterilization, ethylene oxide, gamma irradiation, collagen

Authors:

Jan Vesely 1; Hynek Chlup 1; Tomas Grus 2; Rudolf Zitny 1

Authors‘ workplace:

Faculty of Mechanical Engineering, Czech Technical University in Prague, Czech Republic

1; General University Hospital in Prague, Czech Republic

2

Published in:

Lékař a technika - Clinician and Technology No. 1, 2017, 47, 15-18

Category:

Original research

Overview

In this study, composite tubes wer manufactured from biological collagenous matrix and reinforcing polyester mesh. The effect of sterilization on mechanical properties of this structure was evaluated using inflation-extension tests. Samples were exposed to two types of sterilization (ethylene oxide and gamma irradiation). The control (non-sterilized) samples were also tested. The closed thick walled tube model was used in order to compute stresses within sterilized and control specimens. It was found that the process of sterilization (especially irradiation) dramatically affects the final mechanical properties of the material. These findings should be taken into account when such collagenous material is assumed to be used in tissue engineering.

Keywords:

biological composite, sterilization, ethylene oxide, gamma irradiation, collagen

Introduction

Composite materials are heterogeneous mixtures of two or more homogeneous components, which have been bonded together. In composites, properties or set of properties can be attained which could not have been obtained separately. Many in nature occurring materials can be regarded as composite e.g. bones, blood vessels, woods and others. Manmade composites are used since thousands of years, e.g. straw and natural fibers in bricks, laminated woods, etc. [1].

Over the past few decades, tissue engineering has been focused on development of biological substitutes to restore, maintain, or improve tissue functions. Collagen is the most abundant biological material used for tissue engineering. It is the basic constituent of skin, bones, ligaments and connective tissues. Collagen-based biomaterials have been studied extensively for a variety of biomedical applications, including dialysis membranes, wound dressings and artificial skin. Although native collagen possesses high tensile strength, the chemical treatment necessary for isolation makes the reconstituted collagen very poor in mechanical properties [2, 3]. A possible means to circumvent the problem is to reinforce natural polymer matrix by synthetic fibers or structures. Moreover, the properties of such composite could be modulated through composition of constituents in the material.

Routinely used sterilization process for medical products, e.g. high pressure steam (autoclaving) and dry heat cannot be considered for heat and water sensitive biomaterials like collagen structures [4]. Currently the most widely utilized methods for collagen sponge sterilization are ethylene oxide (EtO) gas infiltration and gamma irradiation.

Ethylene oxide treatment is generally carried out between 30 °C and 60 °C with relative humidity above 30% and a gas concentration between 200 and 800 mg/l. Typically, the process lasts for several hours. Ethylene oxide is highly effective, as it penetrates all porous materials, and it can penetrate through some plastic materials and films. EtO kills all known microorganisms such as bacteria (including spores), viruses, and fungi (including yeasts and molds), and is compatible with almost all materials even when repeatedly applied.

Gamma radiation is very penetrating, and is commonly used for sterilization of disposable medical equipment, such as syringes, needles, cannulas and intravenous sets, and food. It is emitted by a radioisotope, usually Cobalt-60 (60Co) or caesium-137 (137Cs).

Earlier investigations focused on physical or chemical alterations after these two methods [5]. EtO was claimed to alter the mechanical and physical properties of collagen slightly, but with a high risk of toxic residues [5]. Gamma irradiation, once introduced as the simplest and most effective way of sterilization without toxic substances, breaks chemical bonds, decreases tensile strength and modulus, thus affecting the exposed material fundamentally [6, 7].

In our study, composite tubes were manufactured from biological collagenous matrix and reinforcing polyester mesh. The effect of sterilization on mechanical properties of this polymer-based structure were evaluated using inflation-extension tests.

Material and Methods

Tested specimens

Tubular samples of hybrid composite were manufactured using extrusion while the polyester mesh was integrated into biological collagenous matrix. The picture of sample is shown in Fig. 1. Two samples were sterilized using ethylene oxide, two samples by gamma irradiation and two control specimens were left unsterilized.

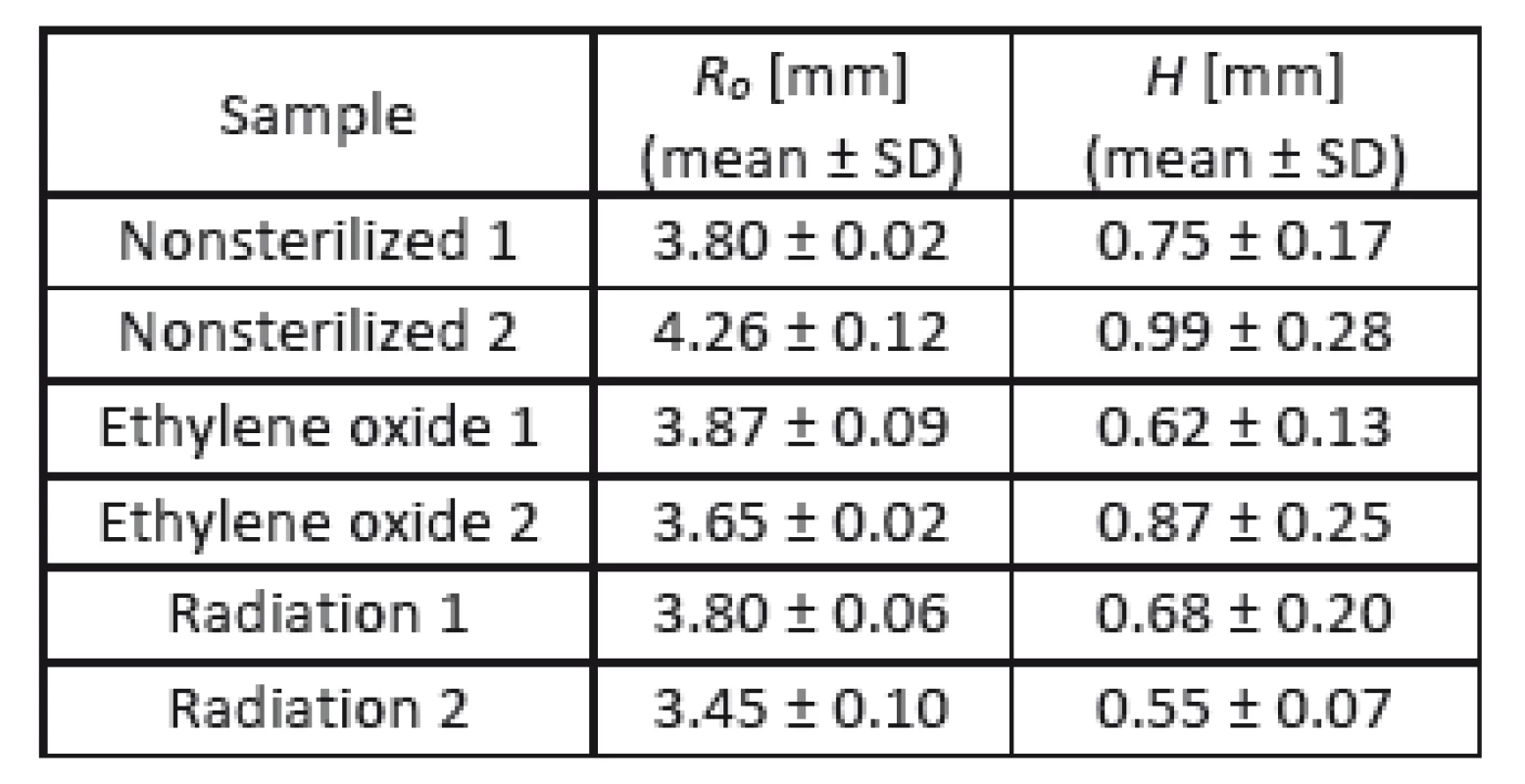

Samples were placed in physiological solution for 24 hours before testing in order to damp them. Prior to the mechanical tests, two rings were cut out from the specimen at both ends, and the mean reference dimensions of the samples (external radius, thickness) were determined by means of image analysis of digital photographs, Tab. 1.

Inflation experiment

Each specimen was hung vertically in the experimental setup with free axial extension at one end (Fig. 2) and marked with liquid eyeliner. The samples were pressurized until destruction using a motorized syringe (Standa Ltd, Vilnius, Lithuania). The intraluminal pressure was monitored by pressure transducer (Cressto s.r.o, Czech Republic). The experiments were performed at room temperature (22 °C). The deformed geometry was recorded by a CCD camera (Dantec Dynamics, Skovlunde, Denmark). In the data post processing, the radius of the sample and length between marks during pressurization was evaluated by the edge detection algorithm in Matlab (MathWorks, MA, USA).

The longitudinal stretch λz and circumferential stretch at outer radius λθ(ro) were computed according Eq. (1). Here L and l is the length between marks in reference and deformed configuration, respectively. Ro and ro is the unloaded and loaded outer radius of the sample, respectively.

The influence of the sterilization was evaluated through circumferential and longitudinal stress, computed according closed thick-walled tube approximation. The circumferential stress σθ(r) created by an internal pressure is computed using Eq. (2). In (2) P is intraluminal pressure, r (ri ≤ r ≤ ro) is deformed variable radius and ri is the loaded inner radius of the specimen. When computing circumferential stress at the outer radius σθ(r = ro) the Eq. (2) passes in Eq. (3).

The longitudinal stress σz (Eq. 4) is computed from force caused by pressure acting on the closed bottom of the tube. This force is distributed on the crossectinonal area of the tube.

Results

The reference dimensions of samples are listed in Tab. 1. Final circumferential stress – stretch curves are plotted in Fig. 3 and axial stress – stretch response is plotted in Fig. 4.

Discussion

In our study, biological composite samples were manufactured from collagenous matrix and reinforcing polyester mesh. The effect of sterilization (ethylene oxide and gamma irradiation) on mechanical properties of this structure were evaluated using inflation-extension tests. This influence was evaluated through circumferential and longitudinal stress computed according closed thick-walled tube approximation.

Fig. 3 and Fig. 4 show that the final mechanical properties are dramatically affected by process of sterilization. The specimens showed very small longitudinal deformation (max. approx. 3.5% - sample sterilized using EtO) in comparison with the circumferential direction. Nonsterilized samples and specimens sterilized by EtO extend during pressurization, while length of irradiated tubes is shortened (Fig. 4). Small axial deformation is, however, determined with relatively high measurement uncertainty which is caused by the limited resolution of digital images.

Control samples showed the most compliant behavior, with large circumferential deformations up to 20%. Specimens sterilized using ethylene oxide are stiffer but the deformation at the destruction point is similar as for control samples. The irradiation has changed behavior of the material completely. Here the breaking strength is close to the samples sterilized by ethylene oxide, but the stiffness is very high. These observations could be interpreted through crosslinking process. During the sterilization, additional bonds are created between individual polymer chains. The more additional bonds are formed the stiffer response is observed in the stress-stretch plot.

Control samples and specimens sterilized by radiation show a sufficient repeatability in stress – stretch curves, however, results of samples sterilized using EtO are dispersed. This could by caused by inaccuracies during manufacture process.

This study proves that mechanical behavior of tubes manufactured from collagen based composite material is affected by sterilization process. These changes in response should be taken into account when such collagenous material is assumed to be used in tissue engineering.

Acknowledgement

This study has been supported by Czech Ministry of Health through grant NV15-27941A.

Ing. Jan Veselý

Department of Mechanics, Biomechanics and Mechatronics

Faculty of Mechanical Engineering

Czech Technical University in Prague

Technická 4,

CZ-166 07 Prague 6

E-mail: jan.vesely1@fs.cvut.cz

Phone: +420 224 352 690

Sources

[1] Prabhuram, T., Somurajan, V., Prabhakaran, S.: Hybrid composite materials, in proc.: Proceedings of the International Conference on Frontiers in Automobile and Mechanical Engineering (FAME 2010), Institute of Electrical and Electronics Engineers, Chennai, India, November 25-27, 2010.

[2] Kannana, R.Y., Salacinskia, H.J., Salesa, K., Butlerb, P., Seifalian, A.M.: The roles of tissue engineering and vascularization in the development of microvascular networks: A review. Biomaterials, 2005, vol. 26, no. 14, p. 1857–1233.

[3] Giusti, P., Lazzeri, L., De Petris, S., Palla, M., Cascone, M.G.: Collagen-based new bioartificial polymeric materials. Biomaterials, 1994, vol. 15, no. 15, p. 1229–1233.

[4] Noah, E.M., Chen, J., Jiao, X., Heschel, I., Pallua, N.: Impact of sterilization on the porous design and cell behavior in collagen sponges prepared for tissue engineering. Biomaterials, 2002, vol. 23, no. 14, p. 2855–2861.

[5] Olde Damink, L.H., Dijkstra, P.J., Van Luyn, M.J., Van Wachem, P.B., Nieuwenhuis, P., Feijen, J.: Influence of ethylene oxide gas treatment on the in vitro degradation behavior of dermal sheep collagen. Journal of Biomedical Materials Research, 1995, vol. 29, no. 2, p. 149–155.

[6] Cheung, D.T., Perelman, N., Tong, D., Nimni, M.E.: The effect of gamma-irradiation on collagen molecules, isolated alphachains, and crosslinked native fibers. Journal of Biomedical Materials Research, 1990, vol. 24, no. 5, p. 581–589.

[7] Liu, B.C., Harrell, R., Davis, R.H., Dresden, M.H., Spira, M.: The effect of gamma irradiation on injectable human amnion collagen. Journal of Biomedical Materials Research, 1989, vol. 23, no. 8, p. 833–844.

Labels

BiomedicineArticle was published in

The Clinician and Technology Journal

2017 Issue 1

-

All articles in this issue

- THE EFFECT OF FLUID ACCUMULATION IN STOMACH ON ELECTRICAL IMPEDANCE TOMOGRAPHY IMAGE OF LUNGS

- EFFECT OF STERILIZATION ON MECHANICAL PROPERTIES OF COLLAGEN-BASED COMPOSITE TUBES

- BIOFEEDBACK AS A NEUROBIOMECHANICAL ASPECT OF POSTURAL FUNCTION

- THE USE OF NONINVASIVE DIAGNOSTIC METHODS IN THE ASSESSMENT OF POSTURAL CHANGES IN UNIVERSITY STUDENTS

- USING PVDF FILMS AS FLEXIBLE PIEZOELECTRIC GENERATORS FOR BIOMECHANICAL ENERGY HARVESTING

- The Clinician and Technology Journal

- Journal archive

- Current issue

- About the journal

Most read in this issue

- THE USE OF NONINVASIVE DIAGNOSTIC METHODS IN THE ASSESSMENT OF POSTURAL CHANGES IN UNIVERSITY STUDENTS

- BIOFEEDBACK AS A NEUROBIOMECHANICAL ASPECT OF POSTURAL FUNCTION

- USING PVDF FILMS AS FLEXIBLE PIEZOELECTRIC GENERATORS FOR BIOMECHANICAL ENERGY HARVESTING

- THE EFFECT OF FLUID ACCUMULATION IN STOMACH ON ELECTRICAL IMPEDANCE TOMOGRAPHY IMAGE OF LUNGS