Evaluation of water absorption rate of tablets by using an Enslin-Neff device

Authors:

Jan Stoniš; Zdenka Šklubalová; Pavel Ondrejček; Petra Svačinová; Hana Hurychová

Authors‘ workplace:

Department of Pharmaceutical Technology, Faculty of Pharmacy Hradec Králové, Charles University in Prague, Hradec Králové, Czech Republic

Published in:

Čes. slov. Farm., 2015; 64, 197-198

Category:

Introduction

Tablets are the most popular dosage form. To ensure their quality, safety and efficiency, tablets are tested using wide spectra of methods. Most of these methods are included in the Pharmacopoeia; however, there are other useful methods that are not included.

In this research paper, the focus was placed on water absorption rate. The method proposed by Bi et al.2) is commonly used. Here, an Enslin-Neff device, generally used in testing of clays and soils in geology3), is used to check water absorption rate of tablets. Tablets were prepared by direct compression of the granules performed by fluid-bed granulation process from corn starch and lactose.

Experimental methods

Granulation

For dying and granulation, a fluid-bed granulator (a Fluid bed dryer and a granulator UNI-GLATT, Glatt GmbH, Binzen, Germany) was used. At first, corn starch was dyed in fluid-bed using a Wurster adaptor. Consequently, dyed corn starch was mixed with lactose in a ratio of 1 : 1 and the mixture was granulated in the fluid-bed granulator using a 10% aqueous solution of Kollidon 25 as the binder.

Tablet production

Tableting mixture was prepared from 250 g of granules and 1.25 g of magnesium stearate (used as the glidant) and pressed into tablets with a diameter of 7 mm (ZWICK ROELL Press, Zwick Roell GmbH, Germany). The compression force was set at 4 kN. Three batches of tablets were prepared using the same approach – CORNLAC 1, CORNLAC 2, CORNLAC 3.

Quality control of granules and tablets

Granules were evaluated for the angle of repose (a Granulate Tester ERWEKA GTB, Erweka GmbH, Germany), Hausner ratio and compressibility index (a Tapped Density Tester ERWEKA SVM 102, Erweka GmbH, Germany), the particle size distribution (a Vibratory Sieve Shaker RETSCH AS200 basic, Retsch GmbH, Germany) and the water content by loss on drying (a Moisture Analyzer PRECISA XM 60, precision 0.001 g, Precisa, Switzerland). The mixture of granules with magnesium stearate was tested for the angle of repose, Hausner ratio and compressibility index again. The mass (an Analytical Balance, precision 0.1 mg, HELAGO SR 120, Helago s.r.o., Czech Republic), the diameter and the height of tablets were estimated as well as the strength (a Tablet Tester SCHLEUNIGER 8M, Pharmatron AG, Switzerland) and the disintegration time (a Disintegration Time Tester ERWEKA ZT 301, Erweka GmbH, Germany).

Water absorption test with an Enslin-Neff device

Water absorption rate was measured with an Enslin-Neff device. The device was filled with a coloured aqueous medium the level of which was kept carefully at the surface of a glass filter. Then, the tablet was laid down and the time to achieve the complete uptake of the liquid was registered (water absorption time in seconds, WAT). The volume of water was measured in the equipment capillary and the tablet was weighted again to express the mass difference. In Fig. 1, the experimental design using the Enslin-Neff device can be seen.

Results and Discussion

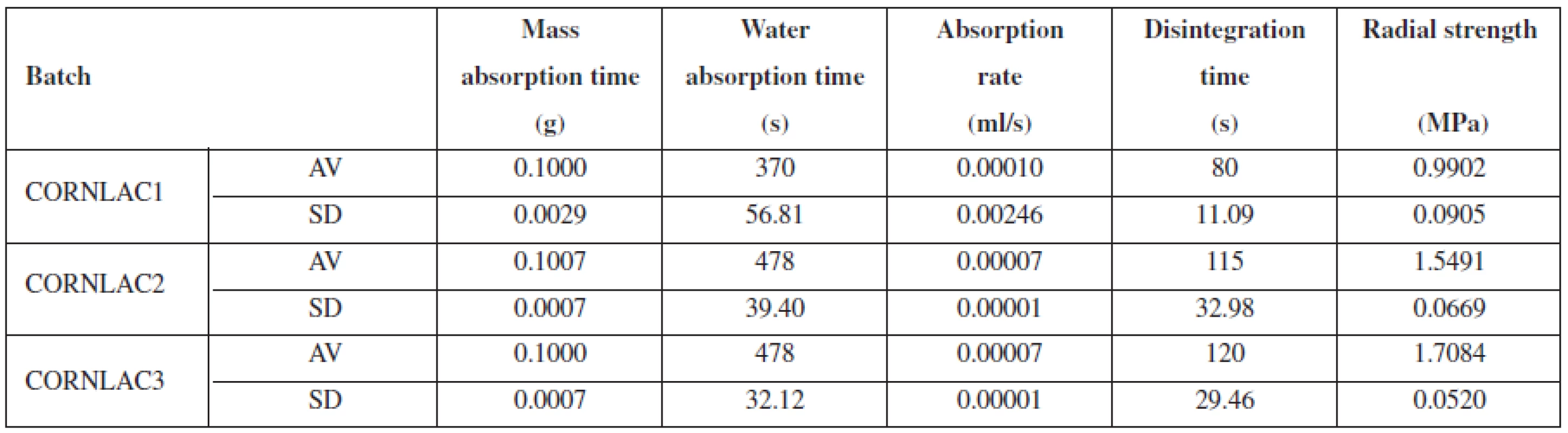

Water absorption rate (ml/s) was calculated using the volume of absorbed water (ml) and WAT (s). The absorbed volume correlates well with the mass difference between a dry and wet tablet. The results of tablet properties evaluation (the average values of 10 values, and the standard deviations) are presented in Table 1.

Out of three compared batches, CORNLAC 1 absorbed the highest amount of water during the experiment with the shortest water absorption time. As can be seen from Table 1, it has also the lowest radial strength and the shortest disintegration time. On the other hand, CORNLAC 2 and CORNLAC 3 possess a much higher radial strength, a longer disintegration time, and a longer water absorption time resulting in a lower absorption rate than that of CORNLAC 1.

Conclusions

An Enslin-Neff device can be used for measuring the water uptake rate of the tablets compressed from granules prepared in a fluid-bed granulator. From the volume difference of the absorbed liquid and the wetting time, the water absorption rate for the tablet can be calculated. Preliminary results show that the radial strength and the water absorption time correlate with each other. This relationship would be further studied.

Research work and poster publication was financially supported by the specific scientific research programme SVV 260 183.

Conflicts of interest: none.

Mgr. Jan Stoniš

Univerzita Karlova v Praze, Farmaceutická fakulta v Hradci Králové

Katedra farmaceutické technologie

Heyrovského 1203, 500 05 Hradec Králové, Czech Republic

e-mail: stonisj@faf.cuni.cz

Sources

1. The Council of Europe. European Pharmacopoeia. 8th ed. Strasbourg: 2013.

2. Bi X. Y., Sunada H., Yonezawa Y., Danjo K. Evaluation of rapidly disintegrating tablets prepared by direct compression method. Drug Dev. Ind. Pharm. 1999; 25(5), 571–581.

3. Kaufhold S., Dohrmann R. Comparison of the traditional Enslin-Neff method and modified Dieng method for measuring water-uptake capacity. Clays Clay Min. 2008; 56(6), 686–692.

Labels

Pharmacy Clinical pharmacologyArticle was published in

Czech and Slovak Pharmacy

2015 Issue 5

-

All articles in this issue

- Methods used in pharmaceutical technology to increase bioavailability of poorly soluble drugs after oral administration

- Level and factors influencing the patients’ satisfaction with the pharmaceutical care in Slovakia

- Drugs and health care expenditure on the aging population

- Drug bioavailability increasing by formulation of liquisolid systems

- Evaluation of compressibility of tableting mixtures using the compaction equation

- Branched polyesters as mucoadhesive carriers of drugs

- Evaluation of water absorption rate of tablets by using an Enslin-Neff device

- Evaluation of the influence of lubricants on the viscoelastic properties of tablets using the stress relaxation test

-

44th Conference drug synthesis and analysis

(Brno, 2nd to 4th September 2015) – Part 1 - Determination of biologically active compounds in the fungi of the genus Cordyceps sinensis by HPLC and NMR

- Determination of CMC of cationic tenside in aqueous and mixed water-alcohol solutions

- A comparison of SiO2-, Cu-, and Ni-supported Au nanoparticles for selective glycerol oxidation to acetic acid*

- Determination of acid-base dissociation constants of newly synthesized arylethanolamine derivatives using capillary zone electrophoresis

- HPLC method for stability evaluation of pharmaceutical preparations containing sodium picosulfate

- The use of 2,6-dichloroquinone-4-chlorimide for quantitative determination of phenylephrine hydrochloride in combined tablets with paracetamol and chlorpheniramine maleate

- The utilization of radionuclide X-ray spectrometry in the determination of elements in medicinal plants and medicinal products used as antianemics

- On-line hyphenated capillary electrophoresis and tandem mass spectrometry used for the analysis of selected biogenic amines in grape leaves

- Validation of spectrophotometric methods of assaying metronidazole in capsules

- Czech and Slovak Pharmacy

- Journal archive

- Current issue

- About the journal

Most read in this issue

- Methods used in pharmaceutical technology to increase bioavailability of poorly soluble drugs after oral administration

- Level and factors influencing the patients’ satisfaction with the pharmaceutical care in Slovakia

- HPLC method for stability evaluation of pharmaceutical preparations containing sodium picosulfate

- The use of 2,6-dichloroquinone-4-chlorimide for quantitative determination of phenylephrine hydrochloride in combined tablets with paracetamol and chlorpheniramine maleate